Click any photo below to view gallery.

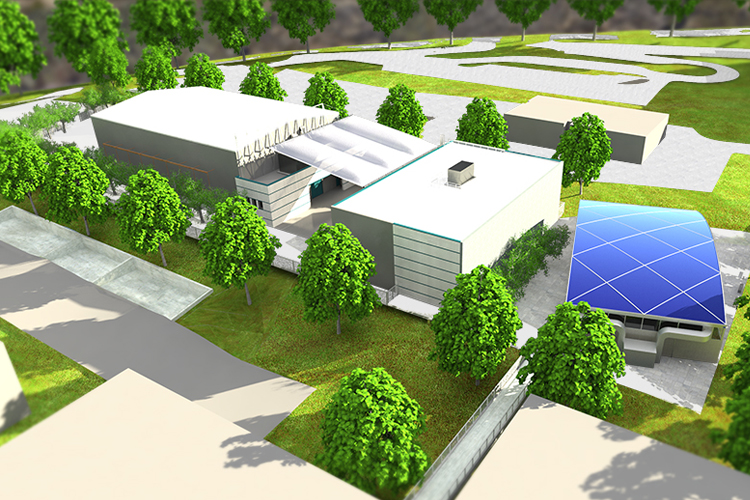

Work Yard between the Shops Building on the right, the vestibule building housing services on the left and the faculty offices and meeting space directly ahead.

Sound stage interior showing overhead catwalks and grid system to support lighting and scenery. Also shown is HVAC system routed into stage sets (that’s where everyone is working).

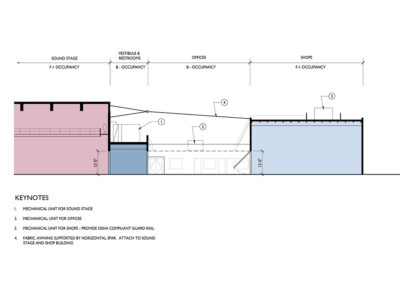

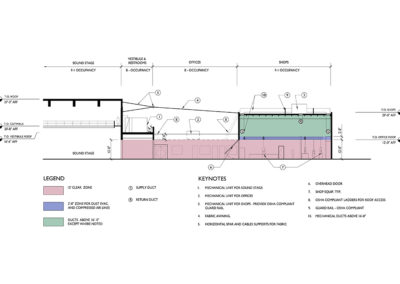

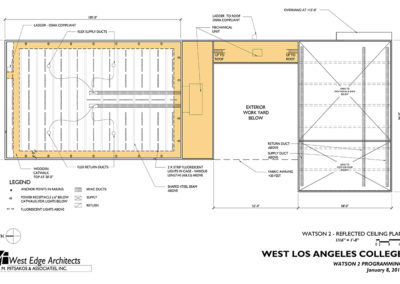

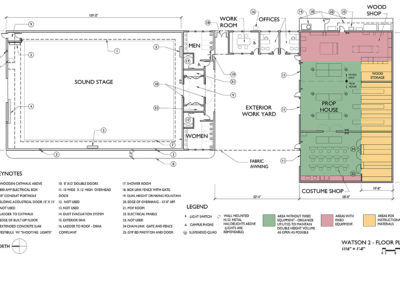

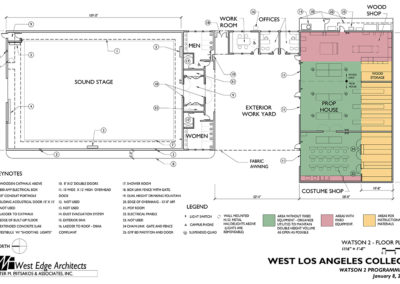

Building plan in context. Blue = shops and offices, pink = sound stage, dark blue = vestibule and services.

Work Yard between the Shops Building on the right, the vestibule building housing services on the left and the faculty offices and meeting space directly ahead.

Sound stage interior showing overhead catwalks and grid system to support lighting and scenery. Also shown is HVAC system routed into stage sets (that’s where everyone is working).

Building plan in context. Blue = shops and offices, pink = sound stage, dark blue = vestibule and services.

Watson Center: West Los Angeles College

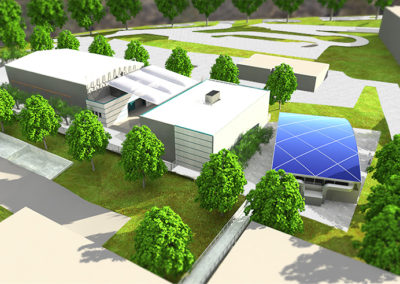

CAMPUS BUILDING | West Los Angeles College, 2016 | Planned to create a realistic working environment, the new Watson Center will house the Motion Picture & Television Production Crafts (MPTV) program will facilitate instruction in the full range of skills required in modern film production. The complex is composed of a new sound stage with overhead catwalks, a set fabrication shop, prop shop and costume shop, outdoor work yards, exterior set staging and a trailer yard for mobile equipment. The outside wall of the sound stage will support street scene backdrops for filming. Affiliated lecture spaces, departmental and faculty offices are located in the Aviation Technology (AT) Complex. These spaces, located on the second floor of the AT-A Building, will be connected via a bridge to the ground level of the Watson Center.

The program components of the Center are arranged on the site to create usable outdoor instructional space between the buildings. The resulting work yard is shaded by fabric “pillowcases” that are inflated to form a semi-translucent roof. These are tethered into place between the buildings. Their shape allows wind to pass around them, never building up any significant force. This strategy eliminates the need for highly tensioned cables (and the structure to resist them) normally required to stretch fabric structures into the proper configuration and resist wind forces, leading to a significant budgetary savings.

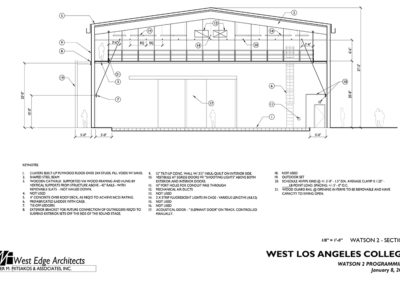

The exterior walls of the sound stage and most of the perimeter of the shops building are tilt-up concrete panels. The extent of the tilt up panels was determined by the maximum number of panels that could be lifted into place in one day within the constraints of the site. The balance of the walls are concrete masonry units, 12-inch for the taller walls and 8-inch for the lower walls. While the roofs were heavily insulated, and the west wall of the facility will be shaded from direct radiation by back-drop assemblages, the interior of all walls were to receive insulation more for sound than as a means to prevent heat gain. This did not challenge the energy budget of the building the way you would expect, since the HVAC system in Sound Stage Building is utilized in a manner different from a more conventional instructional building. The heat is really never turned on. Instructors and students wear coats or vests until the set lighting warms the interiors. The air-conditioning system is run only during set up times and turned off during shooting.

Early on in the process, the design incorporated a much more elaborate network of catwalks with clear head-height throughout. This design would allow access to virtually any point above the floor area of the sound stage. While permitting unlimited access and flexibility in arranging sets and lighting, it proved to be a very costly approach to meeting the requirements. Along with the faculty, the design team visited a recently constructed sound stage facility in the region that accomplishes production shooting with a far less extensive catwalk system. After interviewing the managers of that facility as to the types of productions that were being accommodated, safety and other technical aspects of the configuration, the approach to the Watson Center sound stage was reconcepted to meet both the operational requirements and budget.

The new Watson Center will allow the MPTV Program to expand to meet pent-up demand for enrollment. Since it had been working in makeshift conditions within the hangar space of the Aviation Technologies Building, MPTV programs also impinged on the scheduling and execution of those programs. Construction of the Watson Center will also allow the Aviation programs to expand to meet demand for enrollment.